The Rotary Lane Material Cabinet by HYVODA is designed for high-density storage of small-batch, multi-category materials with precise control of retrieval quantities. It features multi-layer rotary lanes, intelligent identification, and centralized management, enabling space-efficient storage, automated retrieval, and controlled pick quantities. Each lane can be configured for different material types and automatically records retrieval/return data (operator, time, quantity). Supports simultaneous multi-lane operation and real-time data sync to remote management platforms. Ideal for electronics manufacturing, automotive workshops, pharmaceutical distribution, and logistics, improving material organization, reducing errors, and boosting turnover efficiency.

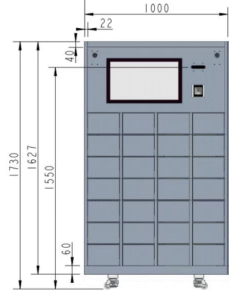

Drawer-Type Weighing Material Cabinet

Drawer-Type Weighing Material Cabinet is an integrated storage and weighing solution developed by HYVODA for small-to-medium batch materials that require dust-proof storage, easy access, and