Drawer-Type Weighing Material Cabinet is an integrated storage and weighing solution developed by HYVODA for small-to-medium batch materials that require dust-proof storage, easy access, and precise inventory control. It features smooth sliding drawers with built-in high-precision weighing sensors, enabling real-time weight monitoring and automatic inventory without removing materials. The intelligent system reduces dust contamination, manual counting time, and material loss in deep drawers. Compared with traditional vertical cabinets, the pull-out drawer design provides direct, ergonomic access for frequent use while each drawer functions as an independent weighing unit. Ideal for electronics assembly, precision manufacturing, laboratories, and automotive parts management, helping achieve clean, efficient, and traceable material control.

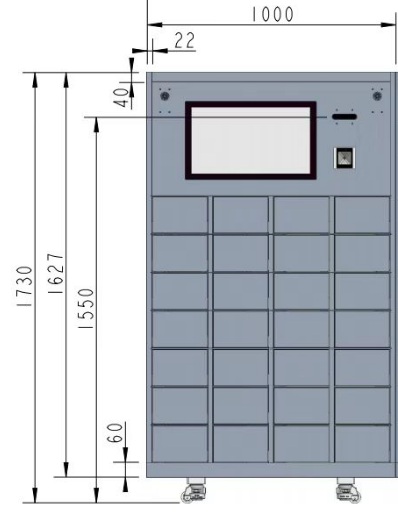

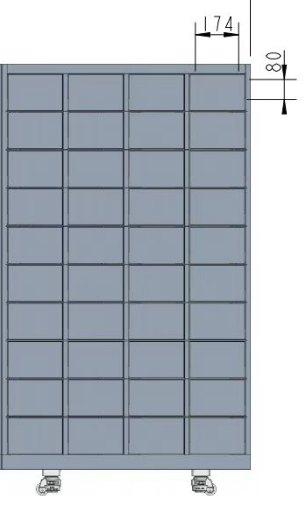

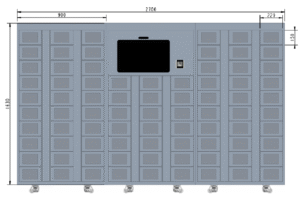

Weighing Material Cabinet Design – Small Compartment Cabinet

The Weighing Material Cabinet (Small Compartment Version) by HYVODA is designed for managing small, micro-quantity materials such as electronic components, precision hardware, lab reagents, and