Intelligent Weighing Cabinet by HYVODA is a high-precision material management solution designed for accurate weight measurement, traceable inventory, and strict material control. It combines one-compartment-one-scale technology, intelligent data acquisition, and multi-modal access control to enable automatic weight detection, real-time inventory updates, and full-process data traceability. This system solves common issues in traditional material management, such as manual weighing errors, paper-based records, tracking difficulties, and inventory inaccuracies. Each compartment has an independent sensor capable of detecting micro-weight changes (±0.2g). It supports centralized computer management, automatically recording key data for each access event (material, operator, time). Essential for industries like electronics, chemicals, pharmaceuticals, food processing, and scientific research, it ensures refined material management and compliance with quality standards.

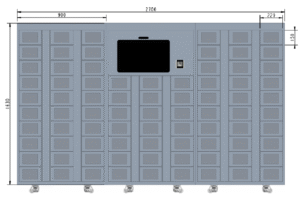

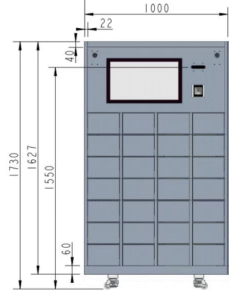

Drawer-Type Weighing Material Cabinet

Drawer-Type Weighing Material Cabinet is an integrated storage and weighing solution developed by HYVODA for small-to-medium batch materials that require dust-proof storage, easy access, and