The Weighing Material Cabinet (Small Compartment Version) by HYVODA is designed for managing small, micro-quantity materials such as electronic components, precision hardware, lab reagents, and medical consumables.

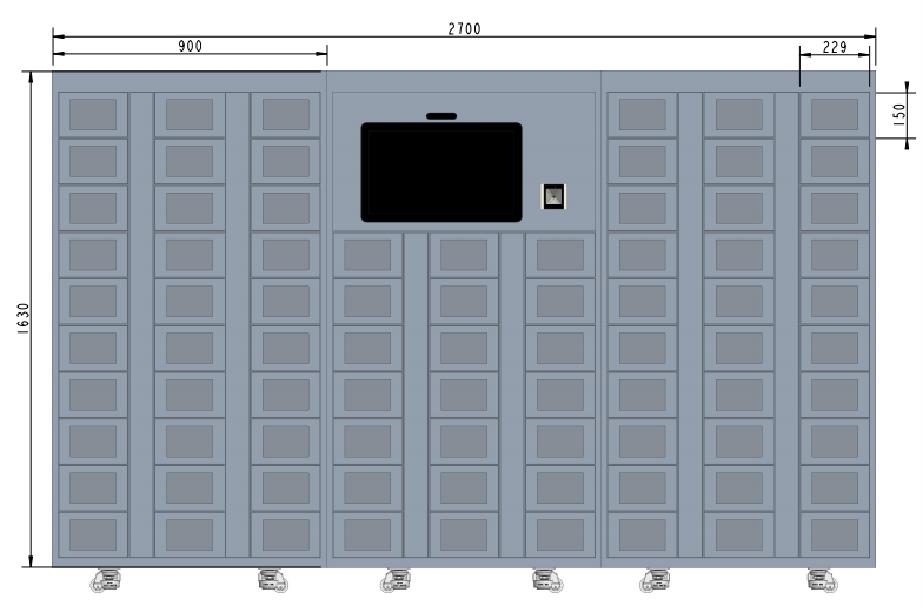

It features a high-density small-compartment layout, micro-precision weight sensors, and intelligent inventory management to solve common issues: disorganized storage, inaccurate manual weighing, slow inventory counting, and difficulty tracking tiny high-value items. With up to 51 mini compartments in a compact main-sub cabinet, it saves space while ensuring accurate measurement and traceability. Ideal for electronics manufacturing, precision engineering, laboratories, and medical device industries, it enables efficient management of micro-scale materials.

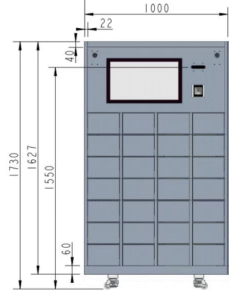

Drawer-Type Weighing Material Cabinet

Drawer-Type Weighing Material Cabinet is an integrated storage and weighing solution developed by HYVODA for small-to-medium batch materials that require dust-proof storage, easy access, and