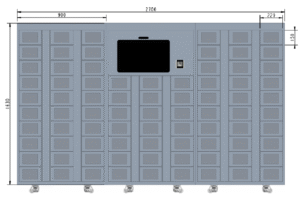

Weighing Material Cabinet (Large Compartment Version) is a heavy-duty storage and weighing solution designed for large and bulky materials such as mechanical parts, industrial consumables, and tool assemblies. It combines high-load weighing sensors, oversized compartments, and an intelligent control system to enable secure storage, real-time weight monitoring, and automatic inventory management. With a reinforced structure and a load capacity up to 30 kg per compartment, the cabinet easily accommodates heavy or long items (e.g., shafts, fasteners, tool kits) while ensuring accurate weight tracking and organized access.This system helps solve common challenges like difficult weighing, messy storage, manual recording errors, and material damage during handling. Ideal for machinery manufacturing, automotive workshops, warehouses, and industrial maintenance centers seeking efficient and traceable management of large materials.

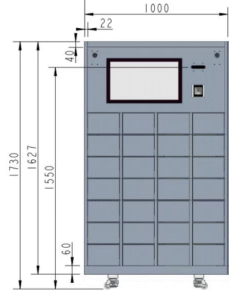

Drawer-Type Weighing Material Cabinet

Drawer-Type Weighing Material Cabinet is an integrated storage and weighing solution developed by HYVODA for small-to-medium batch materials that require dust-proof storage, easy access, and