The HYVODA RFID Intelligent Tool Cabinet is an advanced tool management solution designed to solve common industrial challenges such as time-consuming inventory, poor traceability, and frequent tool misplacement or loss. Powered by UHF RFID technology and integrated with IoT and big data, it enables intelligent full-process management covering storage, retrieval, inventory, traceability, and maintenance. With centralized computer-based control, multi-modal identity verification, and automatic tool circulation recording, the system replaces manual registration and improves accuracy and efficiency. It is ideal for small to large-scale tool management and helps enterprises achieve refined, digital asset control.

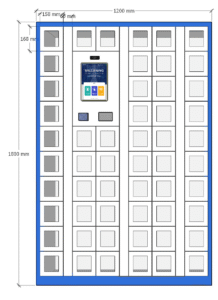

RFID 10-Door Grid Main Cabinet

RFID 10-Door Grid Main Cabinet by HYVODA is designed for small-batch, multi-category tool storage. It uses UHF RFID with 10 independent grids for one-type-per-grid storage,