Hydrogen is often viewed as dangerous, but in North America it has been safely used for decades in refining, chemicals, metals, electronics, and energy projects under strict standards.

Where Is Hydrogen Safely Used?

Why Safety Is Always the First Question

Hydrogen is often labeled in the media as “dangerous” or “explosive.”

For many companies, the first impression of hydrogen is concern about potential risks such as leaks or explosions during use.

If I were in your position, I would have the same concerns.

What Are the Real Risks If Hydrogen Is Not Managed Safely?

In the North American market, safety is always the first issue when companies consider introducing any new energy source or industrial gas.

For many decision-makers, hydrogen is naturally associated with flammability, explosion risks, and potential danger to personnel.

However, what North American companies truly worry about is not hydrogen itself, but the consequences of a safety incident.

These consequences go far beyond production shutdowns and may include legal liability, insurance claims, regulatory compliance issues, and long-term brand damage.

In most cases, companies are not afraid of higher costs — they are cautious about responsibility and risk exposure.

That is why safety-related decisions are often approached with extreme care.

At the same time, as industrial applications of hydrogen mature, companies have found that properly understanding and managing hydrogen-related risks can deliver long-term returns, improved operational efficiency, and significant environmental benefits.

How Is Hydrogen Safety Evaluated in Industrial Use?

In industrial environments, the most convincing proof of safety does not come from laboratory tests alone.

Real-world conditions always involve uncertainties that cannot be fully replicated in controlled experiments.

What truly builds confidence is long-term industrial usage combined with established safety standards.

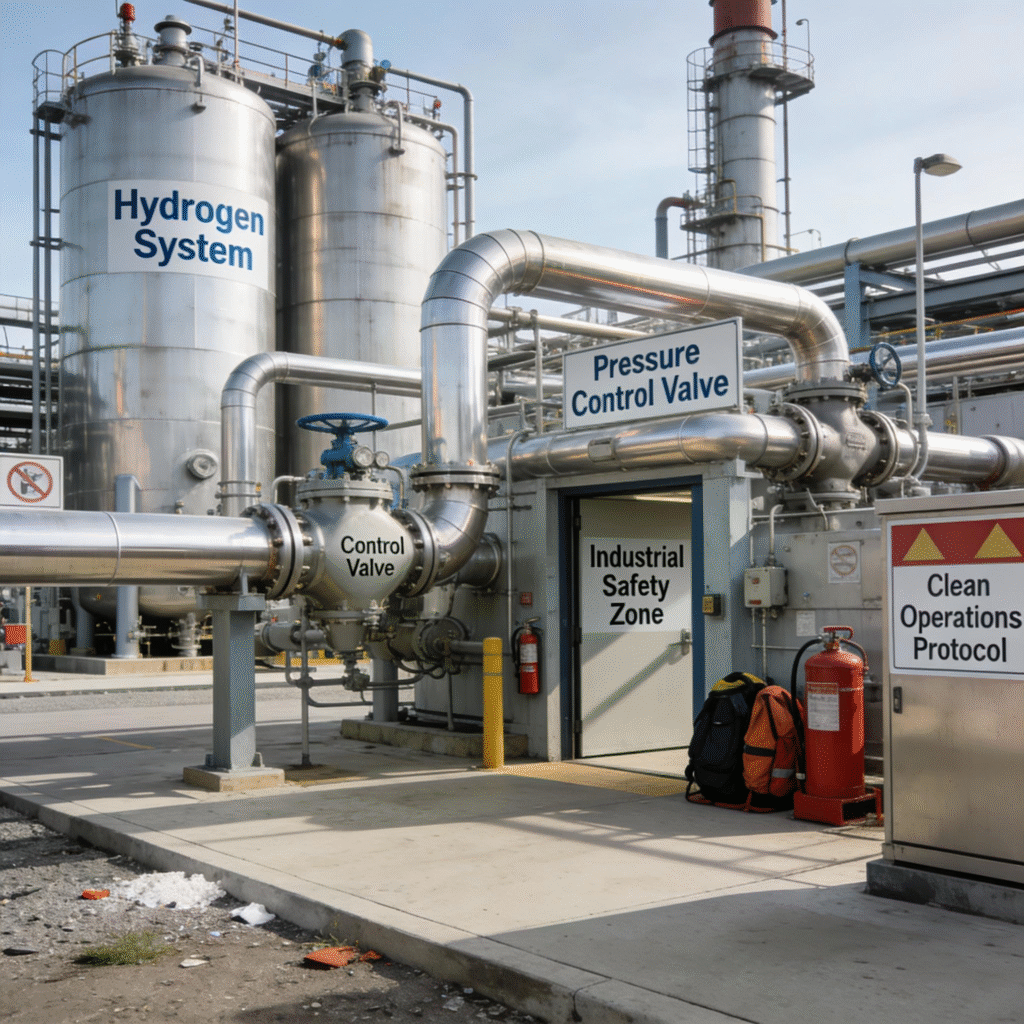

In North America, hydrogen systems are governed by widely recognized standards such as OSHA, NFPA, and ISO.

These frameworks ensure that hydrogen can be safely controlled even under high-pressure, high-temperature, and continuous-operation conditions commonly found in industrial settings.

Industrial Applications of Hydrogen in North America

Oil and Chemical Industries

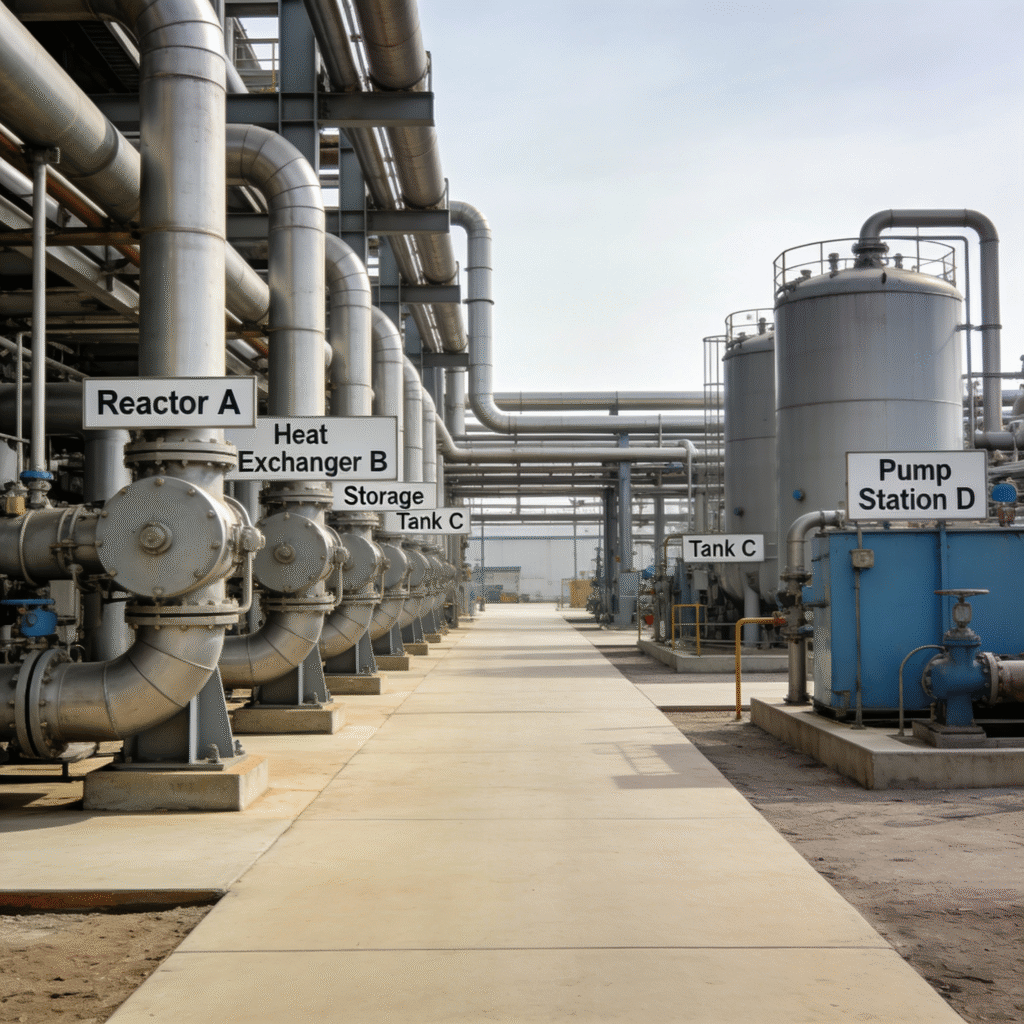

In North American petrochemical and refining operations, hydrogen has been used for decades in processes such as refining and hydrotreating.

These processes typically operate under high temperatures, high pressures, and continuous production conditions, where safety requirements are extremely strict.

Companies rely on redundant safety systems, real-time monitoring, and emergency response plans to ensure stable operation.

As a result, hydrogen use in these industries has proven not only safe and reliable, but also beneficial in improving efficiency, meeting regulatory requirements, and reducing the overall cost of incidents.

Steel and Metal Processing Industries

In steel and metal processing, hydrogen is commonly used in reduction processes and heat treatment steps.

These industries are characterized by continuous production, complex processes, and demanding environments involving high temperatures and pressures.

Therefore, gas stability and safety control are critical.

Typical safety measures include system-level design, leak detection mechanisms, and structured employee training programs.

Long-term use has shown that hydrogen can improve process precision, support energy efficiency goals, and reduce operational risks.

Electronics and Semiconductor Manufacturing

In electronics and semiconductor manufacturing, hydrogen is used for cleaning processes and protective atmospheres.

This industry is extremely sensitive to leaks and operates in cleanroom environments where safety tolerance is close to zero.

Companies rely on standardized operating procedures, real-time detection systems, and regular training to maintain safety.

Beyond safety, hydrogen use also contributes to improved process stability and lower defect rates.

Energy and Transportation Demonstration Projects

In North America, hydrogen is also applied in energy and transportation demonstration projects, including fuel cells, hydrogen refueling stations, and energy storage systems.

These projects follow strict monitoring requirements and standardized operational procedures, and many have operated for years without major safety incidents.

Such projects demonstrate that hydrogen applications can be highly controllable, safe, and scalable, providing valuable references for broader industrial adoption.

Common Factors Behind Safe Hydrogen Use

Across these industries, several common factors enable the safe use of hydrogen:

- Standardized system design and compliance with regulations

- Continuous monitoring and early risk detection

- Ongoing training and emergency response drills

- Clear accountability and closed-loop management systems

These cases show that hydrogen safety is not merely a technical issue, but the result of comprehensive management and system-level engineering.

Final Perspective

For companies, the key question is not whether hydrogen technology is inherently safe, but whether proper management and risk control capabilities are in place.

Before adopting hydrogen, North American companies typically evaluate hydrogen production methods, cost structures, process compatibility, and expected return on investment.

Long-term industrial experience shows that hydrogen applications built on standards and systematic management can be safe, controllable, and commercially valuable.