Why Hydrogen Safety Is Often Misunderstood

Hydrogen is frequently perceived as dangerous due to its association with explosions, high energy density, and historical incidents. However, modern hydrogen systems operate under a fundamentally different safety philosophy than early industrial applications. Today, hydrogen safety is governed by engineering design, quantitative risk assessment, and international standards rather than assumptions or fear.

Hydrogen disperses vertically faster than natural gas, reducing accumulation risk.

Myth 1 – Hydrogen Is More Dangerous Than Conventional Fuels

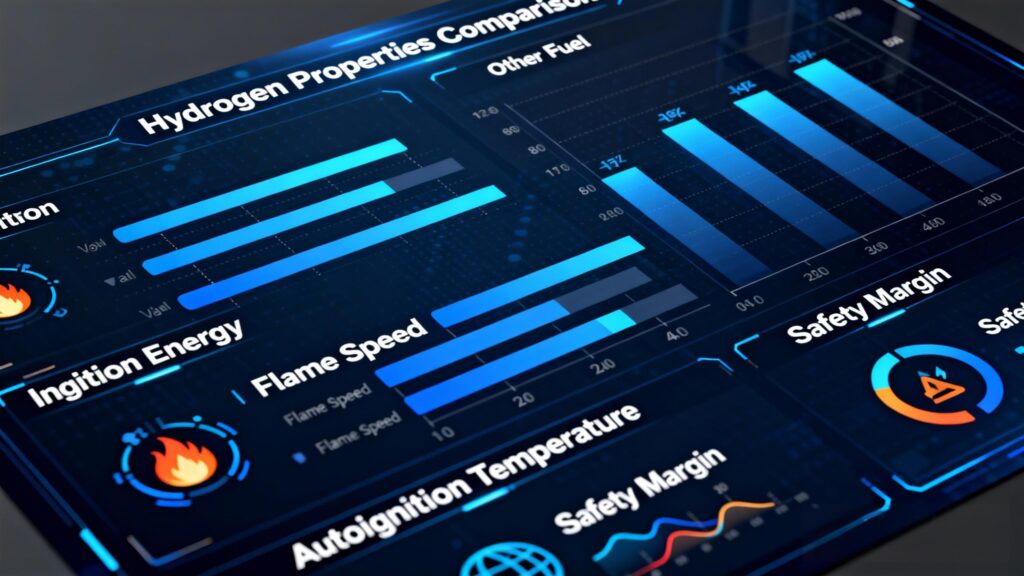

Fact: Hydrogen behaves differently, not more dangerously.

Compared to natural gas or gasoline vapors, hydrogen has the lowest molecular weight and disperses vertically at high speed when released. This rapid dispersion significantly reduces the duration of flammable concentration in occupied zones.

Myth 2 – Small Hydrogen Leaks Always Lead to Explosions

Explosions require precise and simultaneous conditions.

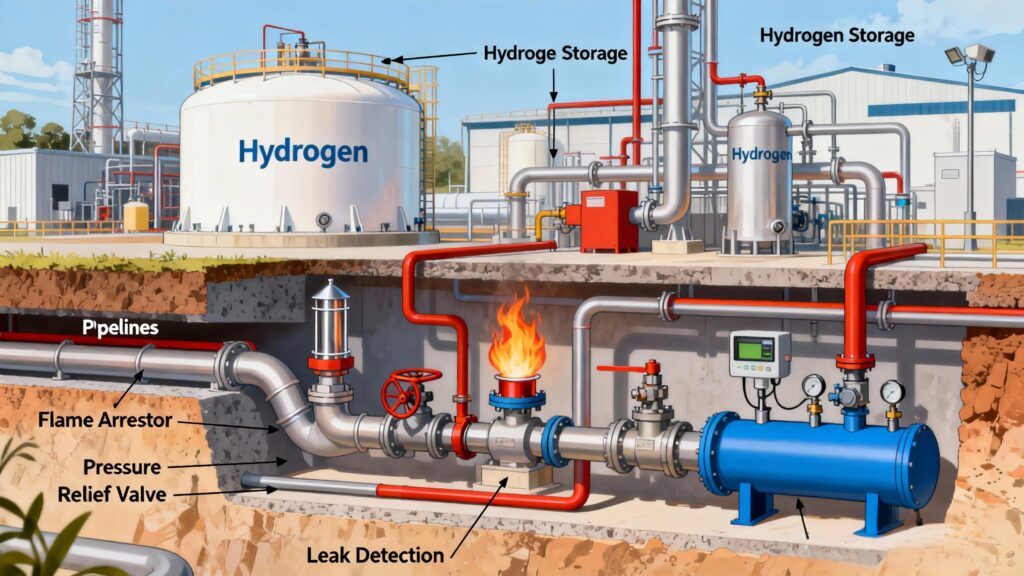

A hydrogen explosion requires three conditions: concentration within flammability limits, ignition, and confinement. Modern hydrogen systems are intentionally designed to eliminate at least one of these factors through ventilation, monitoring, and control logic.

Typical hydrogen safety system including sensors, ventilation, and automatic shutdown.

Myth 3 – Hydrogen Flames Cannot Be Detected

Fact: Detection systems outperform human perception.

While hydrogen flames are nearly invisible, industrial systems use UV/IR flame detectors, catalytic sensors, and continuous gas monitoring capable of detecting leaks within milliseconds.

Myth 4 – Hydrogen Is Too Light to Be Controlled Safely

Fact: Low density simplifies safety engineering.

Hydrogen’s buoyancy allows for predictable vertical ventilation paths. This property reduces pressure accumulation and thermal exposure, a key advantage in indoor safety design.

Myth 5 – Hydrogen Is Unsafe for Indoor or Urban Use

Fact: Hydrogen is already safely used indoors worldwide.

Hydrogen is routinely used in laboratories, hospitals, electronics manufacturing, and chemical plants under ISO and ASME safety frameworks.

Common hydrogen safety myths explained with engineering facts.

Myth 6 – Most Hydrogen Accidents Are Caused by Hydrogen Itself

Fact: Human and system failures are the dominant cause.

Accident analyses consistently show that non-compliant installation, insufficient maintenance, or bypassed safety systems are responsible for incidents—not hydrogen chemistry.

Myth 7 – Hydrogen Safety Is Too Expensive to Implement

Fact: Safety cost scales with system design, not fuel type.

Hydrogen safety relies on layered controls: sensors, automated shutdowns, ventilation, and control algorithms—comparable in cost to natural gas safety systems.

Myth 8 – Hydrogen Safety Is Still Experimental

Fact: Hydrogen safety is standardized and regulated.

Hydrogen systems are regulated by mature international standards, supported by quantitative risk assessment and third-party certification.

Conclusion – Is Hydrogen Safe?

Hydrogen is neither inherently dangerous nor inherently safe. Its safety depends on engineering discipline, system integration, and operational management. When properly designed, hydrogen systems can achieve safety levels comparable to—or exceeding—conventional fuels.

For a practical comparison of hydrogen supply methods, we recommend reading our in-depth analysis on on-site hydrogen generation versus cylinder supply.

According to the International Energy Agency (IEA) Global Hydrogen Review, hydrogen safety standards are already widely implemented across industrial applications worldwide.