Over the past decade, hydrogen has gradually moved from laboratory discussions to real-world industrial deployment.

In North America, hydrogen is no longer an experimental energy option—it is actively used in refineries, chemical plants, mobility projects, and distributed energy systems.

However, one critical question remains largely overlooked:

Why do some hydrogen projects scale smoothly, while others remain stuck at pilot stage?

From HYVODA’s perspective, after observing multiple international hydrogen projects, the answer is clear:

hydrogen adoption is not limited by technology alone, but by infrastructure readiness.

1. Hydrogen Safety Is No Longer the Core Bottleneck

Hydrogen safety concerns are often the first topic raised in public discussions.

Yet in reality, safety standards for hydrogen are already well-established.

In North America, hydrogen projects routinely comply with frameworks such as:

- NFPA 2 – Hydrogen Technologies Code

- ASME pressure vessel and piping standards

- CSA and ISO hydrogen system certifications

These standards define how hydrogen should be produced, stored, transported, and consumed safely.

The real challenge today is not “Can hydrogen be safe?”

It is “Can hydrogen systems be deployed repeatedly, efficiently, and economically?”

2. Infrastructure Determines Whether Hydrogen Is a One-Off Project or an Industry

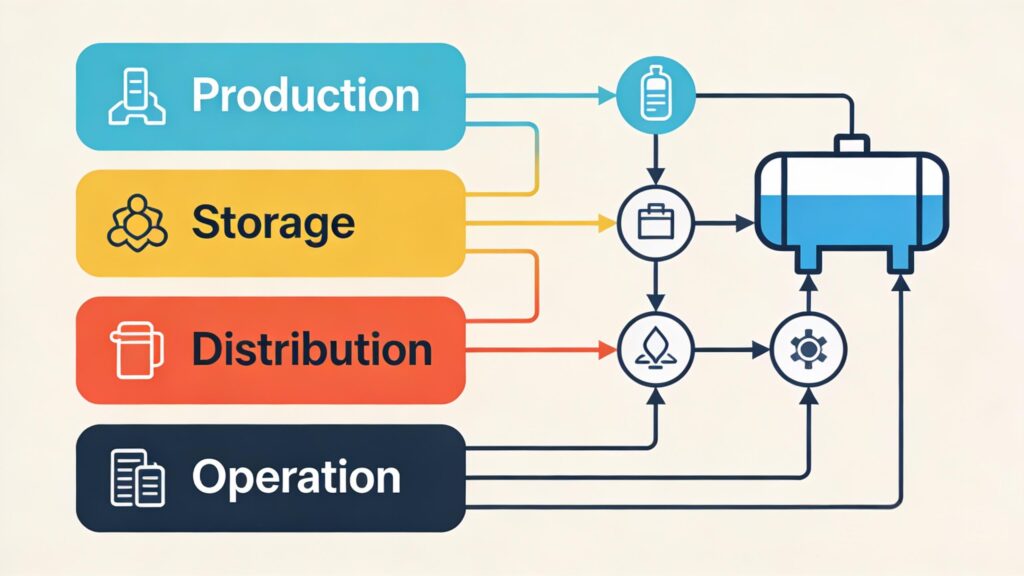

Hydrogen infrastructure readiness can be divided into four layers:

(1) Production Infrastructure

Electrolyzers and reforming units are becoming more efficient, but projects often face:

- Limited access to stable electricity or renewable integration

- Inconsistent hydrogen output affecting downstream users

Without predictable production, hydrogen cannot support industrial continuity.

(2) Storage and Buffer Systems

Hydrogen storage is not only about pressure—it is about system stability.

Industrial users require:

- Buffer tanks to smooth production fluctuation

- Redundant safety valves and monitoring systems

- Materials resistant to hydrogen embrittlement

This is where engineering quality directly determines system lifespan.

(3) Distribution and On-Site Integration

Most hydrogen today is consumed close to where it is produced.

This requires:

- Modular piping systems

- Compact on-site hydrogen units

- Integration with existing industrial workflows

Poor integration often results in high retrofit costs and low utilization rates.

(4) Operation & Maintenance Readiness

A hydrogen system that cannot be maintained locally will never scale.

Successful projects share one feature:

Local teams understand the system, not just the equipment.

3. Why Modular Hydrogen Systems Are Gaining Momentum

One clear trend in North America is the shift from centralized mega-projects to modular hydrogen systems.

Compared with traditional large-scale plants, modular systems offer:

- Faster deployment

- Lower upfront investment

- Easier regulatory approval

- Higher adaptability across industries

For many industrial users, hydrogen is not their core business—it is a tool.

Modularity allows hydrogen to fit into existing operations instead of forcing operations to change.

4. From Equipment Supply to System Thinking

At HYVODA, we believe hydrogen infrastructure readiness requires a shift in mindset.

The market does not need more isolated machines.

It needs integrated hydrogen solutions that consider:

- Site conditions

- Safety compliance

- Operational habits

- Long-term scalability

This system-level thinking is what separates demonstration projects from commercially sustainable ones.HYVODA hydrogen system solutions

5. Infrastructure Readiness Will Define the Next Hydrogen Decade

Hydrogen’s future will not be decided by headlines or policy announcements.

It will be decided on factory floors, energy stations, and industrial sites.

The projects that succeed will be those built on:

- Reliable infrastructure

- Standardized engineering

- Practical operational design

Hydrogen is ready.

The question is whether the infrastructure is.