For decades, industrial facilities have been tethered to the logistical nightmare of high-pressure hydrogen cylinders and tube trailers. But as we pivot toward a decentralized energy future, the conversation is shifting. Methanol-to-hydrogen (MTH) technology is no longer just an alternative; it is the strategic choice for decarbonization. However, selecting the right generator is not a “one-size-fits-all” purchase—it is an engineering decision that balances chemical purity, thermal efficiency, and long-term TCO (Total Cost of Ownership).

1. The Purity Threshold: Why “9s” Matter In the world of hydrogen, purity is the language of performance.

- The 5N Standard (99.999%): If your facility focuses on steel reduction or powder metallurgy, the HYVODA DPH & YPH Series are the workhorses you need. These systems utilize advanced PSA technology to strip away impurities, ensuring your annealing processes remain oxidation-free.

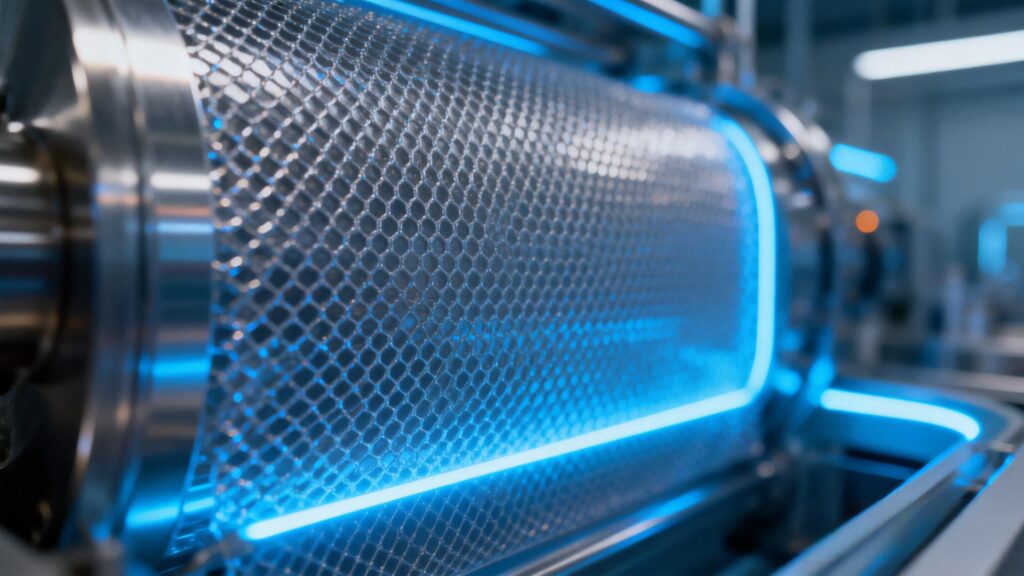

- The 7N-9N Frontier (99.9999% – 99.9999999%): For the semiconductor and fiber optic industries, even a part-per-billion (ppb) of oxygen can lead to catastrophic batch failure. Our CPH Series leverages our proprietary “Hand-torn Steel” grade Metal Membrane to reach purity levels that traditional systems simply cannot touch.

nductor industry.

2. Scaling Without Friction: Flow Rate and Modular Design A common mistake is over-specifying flow rates, which leads to operational inefficiency.

- Decentralized Units (15-100 Nm³/h): Perfect for lab-scale or pilot projects where space is at a premium.

- Industrial Powerhouses (Up to 500 Nm³/h): Our YPH Series is designed for 24/7 heavy-duty cycles. According to the International Energy Agency (IEA), distributed production is key to reducing the “last-mile” cost of hydrogen. At HYVODA, we implement a skid-mounted (plug-and-play) design, allowing you to scale your production by simply adding modules as your demand grows.

3. The “Invisible” Metrics: Dew Point and Catalyst Life Look beyond the brochure. The true value of an MTH generator lies in its stability.

- Dew Point Excellence: A hydrogen stream is only as good as its dryness. HYVODA systems maintain a dew point of <-73°C to -100°C. This is critical for protecting downstream high-precision equipment from moisture-induced corrosion.

- Reactor Longevity: While many competitors offer 5-8 year lifespans, HYVODA’s reactors are engineered for 15 years of service, backed by our high-efficiency catalyst that resists coking and thermal degradation.

Conclusion Transitioning to a HYVODA methanol-to-hydrogen system is more than a utility upgrade; it is a move toward energy independence. By eliminating the risks of high-pressure storage and reducing supply chain costs by up to 50%, you aren’t just producing gas—you are future-proofing your business.

Ready to calculate your ROI? Consult with a HYVODA Technical Expert or Download our Full Selection Catalog.