reliability are becoming equally important. When comparing on-site portable hydrogen generation with traditional hydrogen transportation, the differences are often clearer than expected.

This article explains those differences in a simple way and shows why more companies are choosing on-site solutions such as an industrial hydrogen generator instead of delivered hydrogen gas.

The Hidden Cost of Hydrogen Transportation

Hydrogen transportation usually relies on tube trailers or cylinder bundles. While this method is common, it brings several hidden costs.

First, transportation itself is expensive. Compression, loading, long-distance delivery, and repeated handling can account for a large part of the final hydrogen price. For users with continuous demand, this cost grows quickly.

Second, supply depends on logistics. Delays, weather conditions, or limited local suppliers can interrupt hydrogen delivery. For factories running 24/7, this uncertainty creates production risks.

This is why many industrial users start looking for alternatives to transported hydrogen gas.

Safety Risks During Hydrogen Transport and Storage

Transporting hydrogen means dealing with high-pressure gas cylinders. These cylinders require strict safety procedures, regular inspections, and trained personnel.

Even after delivery, facilities must store hydrogen on site. Large storage volumes increase safety management pressure and compliance costs. For some facilities, this becomes a long-term operational burden.

Reducing transported hydrogen volume is often the first step toward improving overall plant safety.

What Is On-Site Hydrogen Generation?

On-site hydrogen generation produces hydrogen exactly where industrial users need it.

Depending on the application, common solutions include PEM systems and methanol hydrogen generators. Many industrial users with stable demand adopt methanol-based systems for their efficiency and practicality.

An example is the YPH Hydrogen Generator, which produces high-purity hydrogen from methanol through catalytic reforming and PSA purification.

Cost Advantages of On-Site Hydrogen Generators

One major reason companies choose on-site systems is cost control.

Methanol is easy to transport, store, and purchase globally. Compared with compressed hydrogen, methanol supply is simpler and more flexible. When converted on site, the overall hydrogen cost is often significantly lower.

For medium to large users, an industrial hydrogen generator can replace frequent hydrogen deliveries and help stabilize long-term operating expenses.

This is especially attractive for users currently relying on tube trailer hydrogen supply.

Safety Benefits of On-Demand Hydrogen Production

On-site systems generate hydrogen only when needed. This means no large hydrogen storage and no high-pressure cylinders waiting on site.

Modern systems, including High Purity Hydrogen Generators, are designed with explosion-proof structures, automatic control, and safety interlocks. Compared with transported hydrogen, daily operation is easier to manage.

For many factories, this approach reduces safety risk while simplifying compliance requirements.

High Purity Hydrogen for Industrial Applications

Many industrial processes require stable and clean hydrogen. On-site systems can meet these needs consistently.

The YPH Hydrogen Generator series produces 5N high-purity hydrogen for metallurgy, glass manufacturing, electronics, and energy applications. Users with higher purity requirements can integrate additional purification modules.

This level of control is difficult to achieve with delivered hydrogen gas alone.

Portable and Scalable Hydrogen Solutions

Not all users need large systems. In some cases, a Portable Hydrogen Generator is more suitable for decentralized or temporary applications.

On-site generation allows users to scale hydrogen capacity according to actual demand. Whether for a single production line or a larger industrial facility, capacity can be matched without changing the supply method.

This flexibility is one reason many buyers searching for a hydrogen generator for sale prefer on-site solutions.

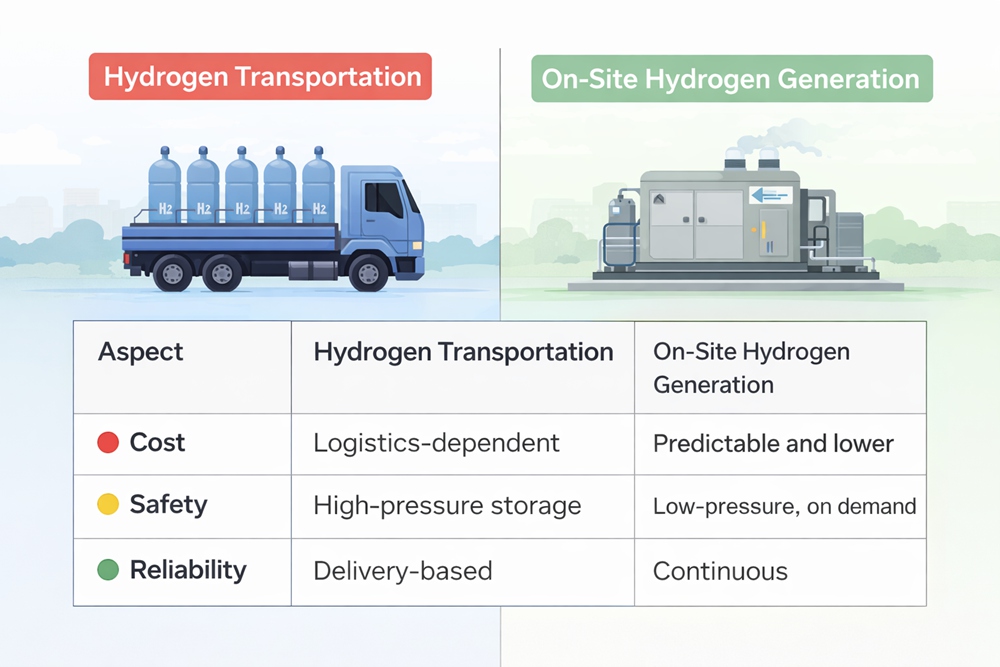

On-Site Generation vs Transportation: A Simple Comparison

| Aspect | Hydrogen Transportation | On-Site Hydrogen Generation |

| Cost control | Affected by logistics | Stable, predictable |

| Safety | High-pressure storage | On-demand production |

| Supply reliability | Delivery-dependent | Continuous |

| Purity stability | Supplier-dependent | Fully controllable |

For many users, the conclusion becomes clear after this comparison.

Is On-Site Hydrogen Generation Right for You?

If your facility consumes hydrogen daily, relies on tube trailers, or faces rising hydrogen costs, on-site generation is worth serious consideration.

Systems such as methanol hydrogen generators and industrial hydrogen generators are already widely used to replace transported hydrogen in real industrial environments.

If you are evaluating options for safer and more economical hydrogen supply, exploring an on-site hydrogen generator gas solution could be a practical next step.

Contact us to discuss suitable hydrogen generator models and configurations for your application.

Our team can help you evaluate capacity, purity, and system layout based on your actual hydrogen demand.