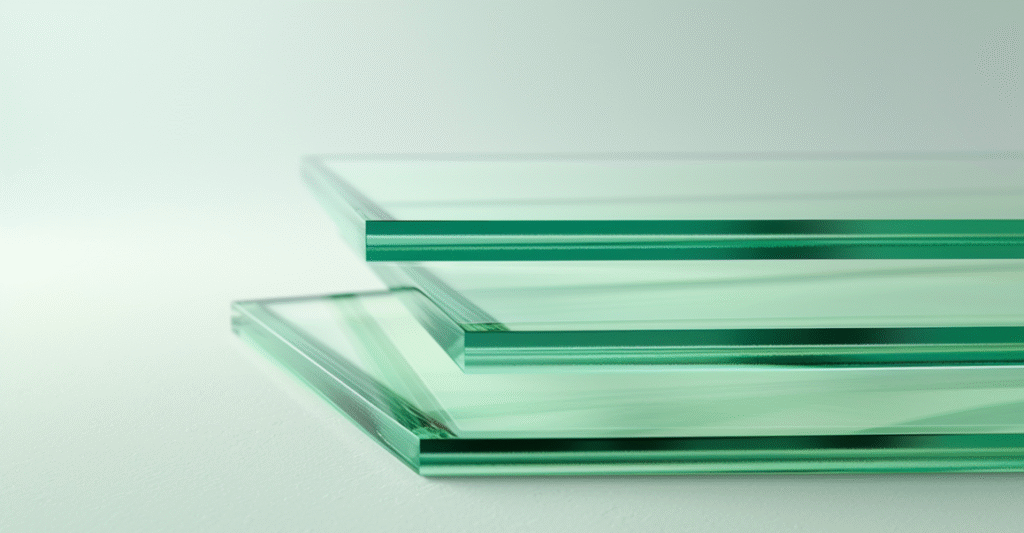

Float glass is one of the most common types of flat glass used in construction and manufacturing. Its production process includes melting, float forming, and annealing. Among these stages, float forming plays a decisive role in determining the final quality and clarity of the glass.

1. Role of Hydrogen in Float Glass Production

Hydrogen plays several key roles during the float glass process.

(1) Protective Atmosphere

To ensure high glass quality and prevent oxidation of molten tin in the tin bath, a mixed protective gas of high-purity nitrogen and hydrogen is continuously introduced. This mixture maintains a stable, clean environment and extends the furnace lifespan.

(2) Density Reduction

Adding hydrogen helps lower the density of the molten glass. Since hydrogen is a lightweight gas, it improves the balance and floatation of the glass ribbon, making the final sheet more uniform.

(3) Improved Transparency

Transparency is a crucial feature of float glass. The right proportion of hydrogen refines the molten glass structure, reducing impurities and bubbles. As a result, the glass becomes clearer and more visually appealing.

(4) Increased Hardness and Durability

Hydrogen helps form micro-structures inside the glass that enhance hardness and reduce UV penetration. This effect improves the glass’s resistance to weathering and extends its service life.

(5) Enhanced Efficiency and Lower Costs

By improving density, clarity, and hardness, hydrogen use increases production efficiency. Manufacturers can achieve higher yields while lowering energy consumption and operating costs.

2. Hydrogen Quality Requirements

When used as a protective gas, hydrogen must meet strict purity standards:

- Oxygen content: < 1×10⁻⁵

- Dew point: -57°C

Such purity ensures stable performance and prevents contamination during float forming.

3. Sustainable Hydrogen Solutions for Glass Manufacturing

HYVODA offers advanced hydrogen generation systems tailored for industries such as glass production. Our industrial hydrogen production solutions provide reliable, energy-efficient gas supply, supporting a cleaner and more sustainable manufacturing process.

To learn more or request a customized solution, please contact HYVODA.