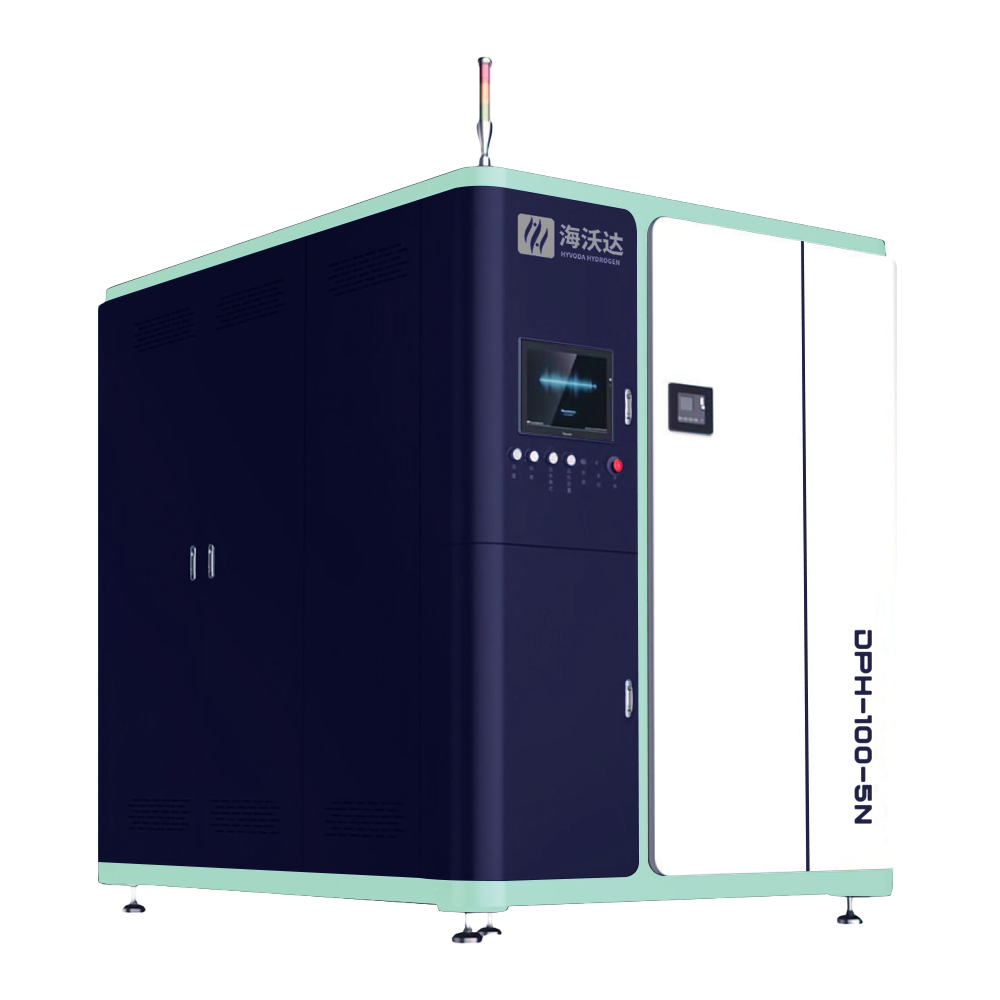

DPH series of high-purity hydrogen generators can produce gas with a purity of 99.999%, and are applied in scenarios with low hydrogen demand (15 to 100Nm/h). They are mainly used to replace hydrogen in cylinders and ammonia decomposition for hydrogen production, significantly reducing hydrogen usage costs and improving product quality.

YPH

The YPH series of high-purity hydrogen production equipment delivers 99.999% hydrogen and is designed for large on-site demand of 150–500 Nm³/h. It replaces tube trailer