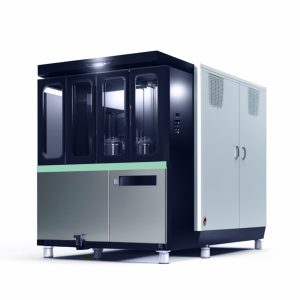

The CPH series ultra-pure hydrogen generator is a product developed and launched by our company after four years of research and development. It combines methanol-to-hydrogen technology with the most advanced “hand-torn steel” grade high-performance metal membrane purification technology in China, capable of producing ultra-pure hydrogen with a purity of 99.9999999%. It has a low hydrogen production cost and can be applied in the production processes of diamond, semiconductors, photovoltaic panels, and scientific instruments.

YPH

The YPH series of high-purity hydrogen production equipment delivers 99.999% hydrogen and is designed for large on-site demand of 150–500 Nm³/h. It replaces tube trailer