ODH series intelligent hydrogen-rich gas generation system uses industrial heat transfer oil as the heating method. The hydrogen produced is mainly used for hydrogen blending in the natural gas part of the gate station or other large-scale hydrogen blending application scenarios. This system is based on the principle of hydrogen production through methanol cracking and can produce hydrogen-rich gas with a combustible gas proportion of over 95% for combustion. The hydrogen production capacity range of a single ODH series device is greater than 1000Nm3/h.

YPH

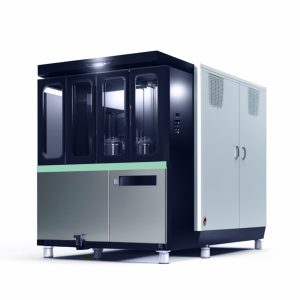

The YPH series of high-purity hydrogen production equipment delivers 99.999% hydrogen and is designed for large on-site demand of 150–500 Nm³/h. It replaces tube trailer