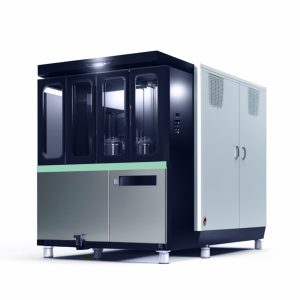

OPH series of high-purity hydrogen production equipment can produce gas with a purity of 99.999%. Applied in scenarios with a high demand for hydrogen (150 to 500Nm3/h), it adopts highly efficient catalysts and a unique self-heating catalytic oxidation heating technology to provide integrated heating for the heat transfer oil system, reducing power consumption, solving the storage and transportation problems of hydrogen, and significantly lowering the cost of hydrogen use.

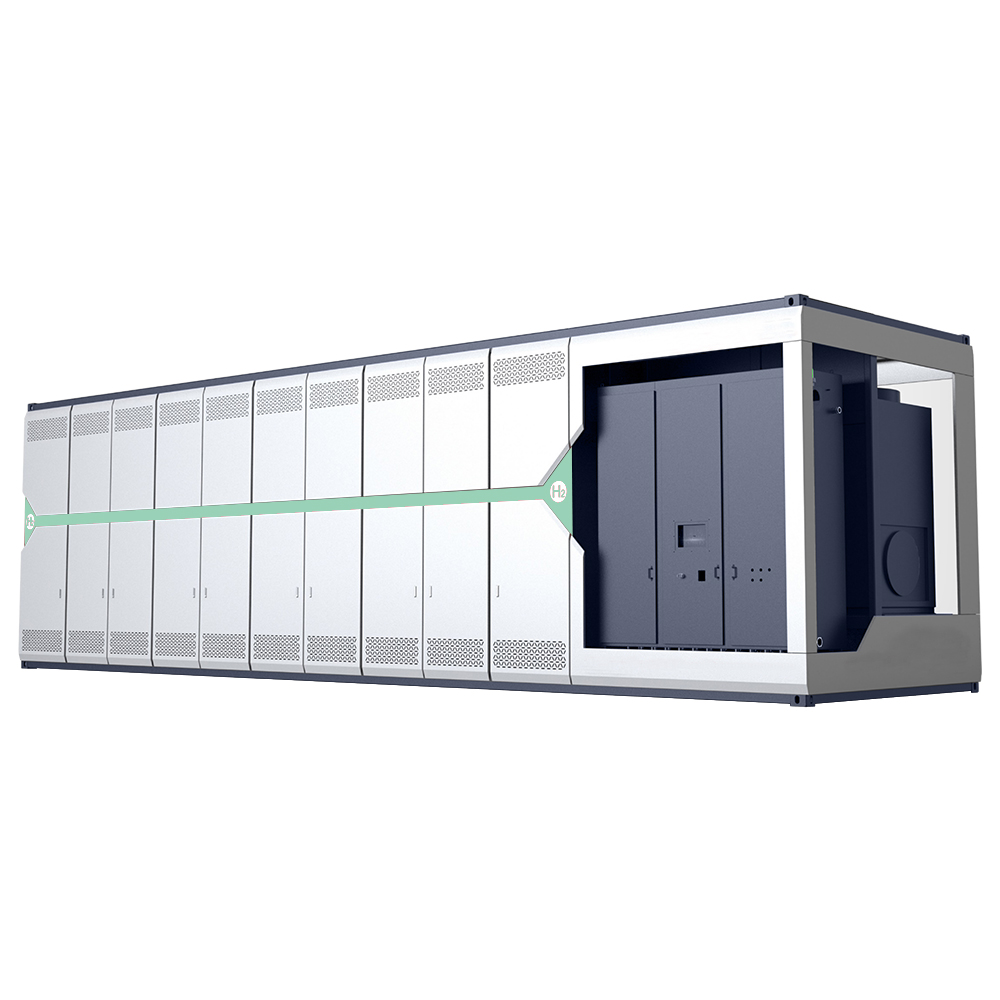

YPH

The YPH series of high-purity hydrogen production equipment delivers 99.999% hydrogen and is designed for large on-site demand of 150–500 Nm³/h. It replaces tube trailer