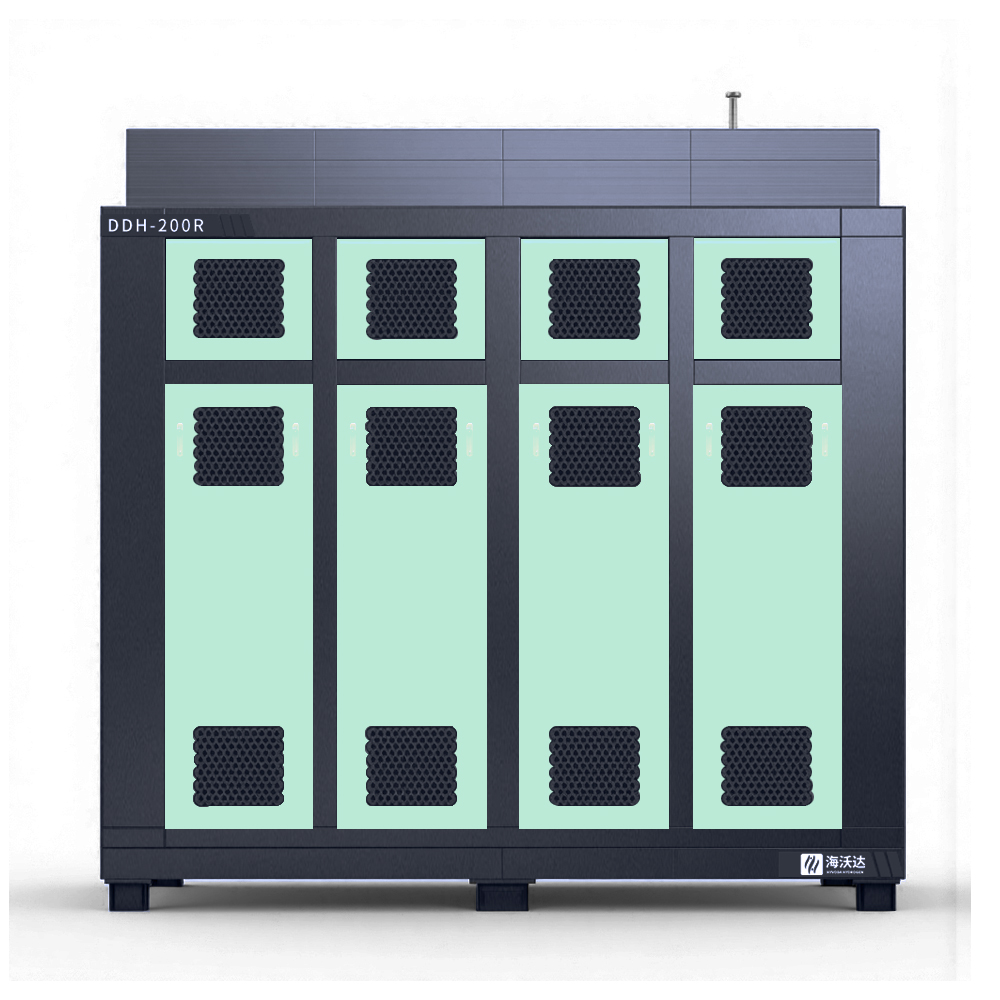

DDH-R series intelligent oxygen-rich gas generation system produces hydrogen-rich gas through electric heating or on-site waste heat utilization. It is mainly used for partial hydrogen blending or complete replacement of non-renewable fuels such as natural gas and liquefied gas. This system is based on the principle of methanol cracking for hydrogen production and can produce hydrogen-rich gas with a combustible gas proportion of over 95% for combustion. The hydrogen production capacity range of a single DDH-R series device is 30 to 1000Nm3/h.

YPH

The YPH series of high-purity hydrogen production equipment delivers 99.999% hydrogen and is designed for large on-site demand of 150–500 Nm³/h. It replaces tube trailer